Mechanical Erection:

Control Through Work Package Monitoring

Balancing Effectiveness and Efficiency in Site Execution

Mechanical Erection Progress Control and Monitoring

Effective control and monitoring of mechanical erection activities are essential to ensuring a project’s success in terms of schedule, cost, and quality. Our methodology is based on structured reporting through Work Package (WP) tables, providing a clear and measurable way to track performance across various disciplines and work areas.

Objectives of the Methodology

This system aims to provide a visual and quantitative tool that supports site engineers, planners, and project managers in:

-

Monitoring erection activities by discipline and area

-

Comparing planned vs. actual progress

-

Identifying delays and inefficiencies

-

Controlling labor productivity

-

Supporting Earned Value Management (EVM)

Key Performance Indicators

The methodology integrates three key concepts of Earned Value Management, represented in clear and concise tables:

-

BCWS (Budgeted Cost of Work Scheduled)

→ Planned quantity/hours of work according to the baseline schedule. -

ACWP (Actual Cost of Work Performed)

→ Actual quantity/hours of work completed on-site as per progress reports. -

BCWP (Budgeted Cost of Work Performed)

→ Budgeted value of the work that has actually been completed.

Table Structure

Each row in the table represents a specific erection activity linked to:

-

Work Package (WP)

-

Discipline and Area

-

Unit of Measurement (UM)

-

Budgeted quantity and hours (BCWS)

-

Actual performance (ACWP)

-

Productivity rate (hours/unit)

-

Scheduled start and finish dates

This allows users to:

-

Track detailed progress for each activity

-

Aggregate data by Work Package or Discipline

-

Compute total planned and actual hours

Benefits of the Methodology

-

Transparent Progress Tracking

Clear visualization of scheduled vs. performed work. -

Work Package Breakdown

Facilitates coordination at the discipline and area level. -

Early Warning System

Real-time detection of performance gaps and delays. -

Supports Reporting

Data can be integrated into dashboards, KPIs, and client reports. -

Data-Driven Decisions

Informs adjustments in manpower and scheduling based on actual site conditions.

Conclusion

By implementing this table-driven methodology and integrating the logic of BCWS, ACWP, and BCWP, project teams can achieve greater control, higher efficiency, and improved predictability during the mechanical erection phases. This approach is scalable, transparent, and adaptable to both digital and field-level monitoring systems.

Risk Assessments – Real Project Insights

In this real case from a Boiler Refurbishment Project (Unit 5 – Reftinskaya GRES), our integrated dashboard highlights:

-

⏱ Schedule delays across key work packages

-

📉 Manhour overruns impacting cost performance

-

📊 Deviations between Planned, Earned & Actual progress

-

🚨 Critical risks, such as underperformance in Gas Duct installation

Our EVM-based methodology supports early warnings, mitigation strategies, and better resource forecasting throughout the EPC lifecycle.

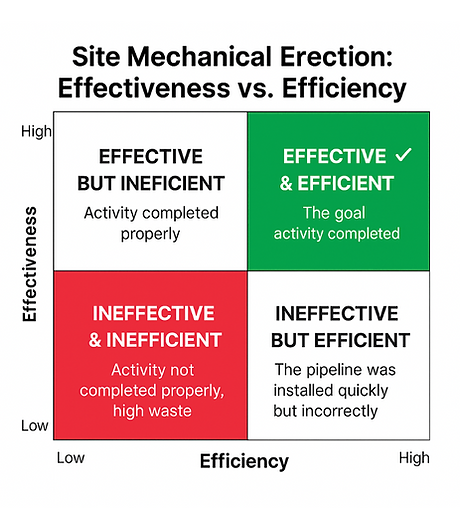

Why Balance Matters

In mechanical erection, speed or precision alone isn’t enough.

True control requires:

-

Effectiveness — doing the right work (BCWP)

-

Efficiency — using optimal resources (ACWP)

Use this matrix to identify your current position and guide corrective action.